The fiberglass pipes can resist the long-term corrosion of various chemical medium such as various acids, alkalis, salts, organic solvents, seawater and sewage. The pipes with different properties can be selected according to different medium types and operating temperatures.

Excellent hydraulic properties

The fiberglass pipes have a very smooth inner surface and low friction resistance (n≤0.0084), which can obviously reduce on-way pressure loss and increase the flow rate. At the same flow rate, we can choose the delivery pump with a smaller pipe diameter or lower power, to reduce the initial engineering investment and energy consumption. (saving the operating cost).

Good designability and a wide range of adaption

To adapt to different requirements of working pressure, medium and stiffness (or laying depth), we manufacture the fiberglass pipes with different pressure grades and special properties.

Pollution resistance and nontoxicity

The smooth inner wall does not form scale, or breed algae or other microorganisms. So there is no secondary pollution to water quality. The pipes made of food-grade resin can be used to convey drinking water.

Less joint and good airtightness

The length of a single fiberglass pipe is usually 12m. The pipes are connected by using double O-rings, and pressure test can be conducted on each connector, which is reliably sealed.

Product specifications

(1) Diameter: DN25-DN3000mm.

(2) Pressure grade: 0.25MPa, 0.6MPa, 1.0MPa, 1.6MPa, 2.0MPa and 2.5MPa.

(3) Single length: 3m, 6m, 9m and 12m.

(4) Stiffness grade: 2,500N/m², 5,000 N/m² and 10,000 N/m².

Note: The pipes of other pressure grades, stiffness grades and length specifications may also be produced at the request of the users.

-

FRP/GRP Sand Pipe

FRP sand pipe(FRP Mortar Pipe/ Fiberglass Reinforced Plastic Mortar Pipe) is a lightweight, high-strength, corrosion-resistant non-metallic pipe.

It is wound on a rotating mandrel layer by layer by the glass fiber with a resin-based body weight according to the process requirements, and quartz sand is evenly laid as a sand layer at a long distance between the fibers. The pipe wall structure is reasonable and advanced, and the role of the material can be fully exerted. Under the premise of satisfying the use strength, the steel degree is improved, and the stability and reliability of the product are ensured. -

FRP/GRP Process Pipe

The FRP process pipe is a kind of conveying pipe used in the desulfurization system. Because of the solution of acid and alkali substances transported in the desulfurization system, the desulfurization pipe must have anti-corrosion, wear resistance and temperature resistance to ensure the good running of desulfurization system.

-

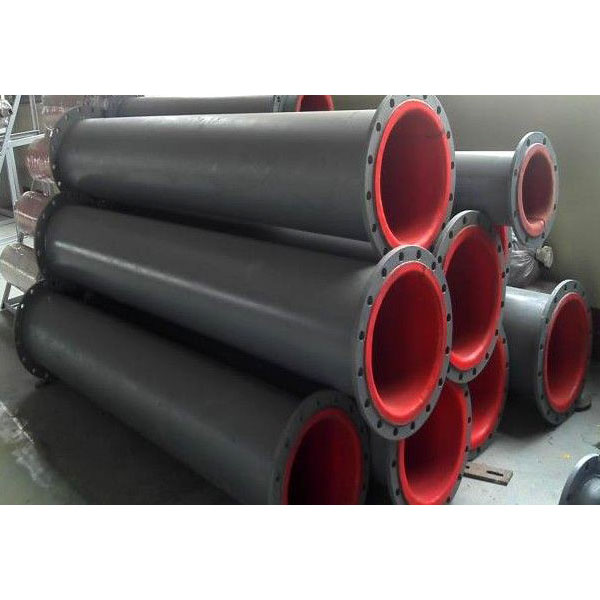

FRP/GRP Composite Pipe

The FRP duct (FRP Composite Pipe) is a non-metallic composite material product with strong tensile strength and higher strength than steel.

-

FRP/GRP Spray Pipe

FRP Spray Pipe(FRP sprinkler pipe) has many advantages such as strong corrosion resistance, smooth inner surface, low energy consumption, long service life, convenient transportation and installation, no maintenance and low overall cost in petroleum, electric power, chemical industry, papermaking, etc. Urban water supply and drainage, factory sewage treatment, seawater desalination, gas transportation and other industries have achieved wide application.

-

FRP/GRP Chimney

The glass fiber reinforced plastic chimney is made of glass fiber reinforced plastic. The product has low cost, short production cycle, long life, convenient processing, simple installation, light weight, high strength and rigidity. It is made of glass fiber reinforced plastic with smooth inner and outer surfaces, anti-aging performance, and corrosion resistance at high temperatures. Excellent performance and other characteristics, and can easily add sprinklers, filters, etc. to absorb harmful components in the flue gas.

-

FRP/GRP Fittings

-Lightweight and high strength: The material density of FRP products is usually 1.8-2.1g/cucm, which is about 1/4~1/5 of steel, and the circumferential tensile strength is ≥300MPa. The specific strength is higher than that of steel.

-Chemical resistance, long service life: FRP has excellent chemical resistance. In corrosive media, FRP exhibits superiority to other materials. Different matrix materials can resist a variety of acids, bases, salts and organic solvents.